Compact enough to fit into the tightest of spaces - yet intelligent enough to adapt to your recording environment - the 8320A is your entry point into the world of Smart Active Monitoring.

8320A

SAM™ Studio Monitor

Smart Active Monitoring (SAM™) and GLM™ calibration technology

Active Crossovers

SPL

100 dB

Frequency Response

55 Hz - 23 kHz (-6 dB)

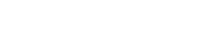

Dimensions

H 242 x W 151 x D 142 mm, with Iso-Pod™ (view in inches)

Transparent and truthful

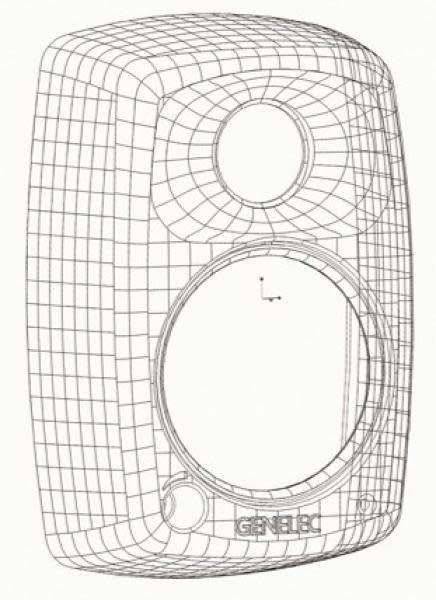

The 8320A provides transparent and truthful reproduction, and with its wide uncoloured sweet spot you are always in a position to make accurate, reliable mix decisions. The recycled aluminium design of it rear-ported enclosure not only provides staggering LF extension from such a compact unit, its curved form and integrated waveguide guarantees precise, detailed performance both on and off axis.

Compact but clever

As a Smart Active Monitor, the 8320A integrates closely with our GLM software via which it can be configured and calibrated for your listening environment, compensating for detrimental room influences to create a truly optimised monitoring solution from mono to immersive. So whether you work in challenging acoustic spaces or need a mobile solution that can quickly adapt to different rooms, the 8320A is your compact but clever monitoring companion.

Technical Specifications

SPL

100 dB

Amplifier Power

50 W Bass (Class D) + 50 W Treble (Class D)

Frequency Response

55 Hz - 23 kHz ("-6 dB")

Accuracy of Frequency Response

± 1.5 dB (66 Hz - 20 kHz)

Driver Dimensions

⌀ 105 mm Bass + ⌀ 19 mm Treble (view in inches)

Dimensions

H 242 x W 151 x D 142 mm, with Iso-Pod™ (view in inches)

Weight

3.2 kg / 7.1 lb

Connections

1 x XLR Analog Input

2 x RJ45 Control

8320A

SAM™ Studio Monitor

Technical Specifications

Compact enough to fit into the tightest of spaces - yet intelligent enough to adapt to your recording environment - the 8320A is your entry point into the world of Smart Active Monitoring.

System Specifications

Frequency Response

66 Hz - 20 kHz (± 1.5 dB)

Low cutoff -6dB

55 Hz

High cutoff -6dB

23 kHz

SPL

Peak SPL Maximum peak acoustic output per pair, at 1 m distance with music material.

≥107 dB

Short term max SPL Maximum short term sine wave acoustic output on axis in half space, averaged from 100 Hz to 3 kHz.

≥100 dB

Long term max SPL Maximum long term RMS acoustic output in same conditions with IEC weighted noise (limited by driver unit protection circuit).

≥94 dB

Self-generated noise

Self-generated noise Self generated noise level in free field on axis (A-weighted).

≤5 dB SPL

Weight

Weight3.2 kg (7.1 lb)

Dimensions

Height

230 mm

Height with Iso-Pod

242 mm

Width

151 mm

Depth

142 mm

Enclosure

Enclosure material

Die cast aluminium

Enclosure type

Reflex port

Drivers

Driver type

Cone

Diameter

105 mm

Driver type

Metal dome

Diameter

19 mm

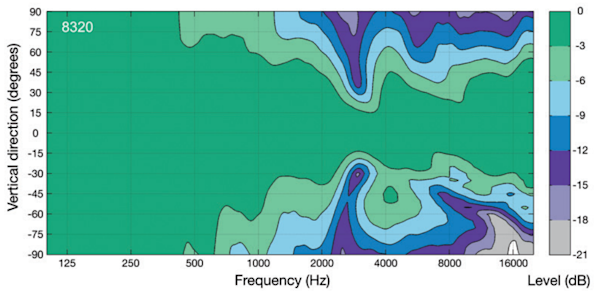

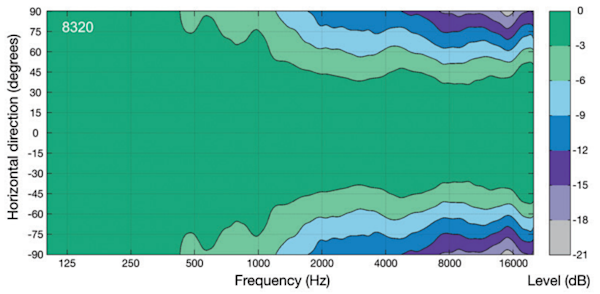

Directivity

Harmonic distortion

> 200 Hz ≤0.5 %

Group delay

The latency at high frequencies from the input to the acoustic output, measured in the analog input:

Extended Phase Linearity in GLM set to OFF

2.8 ms

In Genelec performance graphics, the time of converting the from an electronic input signal to the acoustic output in a Genelec monitor is described by two factors – latency and group delay. The group delay factor can be read in the graphics for a specific frequency. The total frequency-specific input-to-output delay is a sum of the latency and group delay factors. To understand the significance of this total delay, consider that moving a loudspeaker away by 1 meter creates an additional delay of about 3 ms.

Amplifier Section

Amplifiers

50 W Class D

50 W Class D

Mains voltage

100-240 VAC 50/60Hz

Power consumption

ISS Active

≤0.5 W

Idle

≤3 W

Full output

50 W

Signal processing section

Connectors

Input Analog signal input connector XLR female, balanced 10 kOhm.

2 x Control Two CAT5 (RJ45) GLM Network connectors for computer control using the Genelec Loudspeaker Manager (GLM) software.

Crossover

Product Variants

Product codes

Compatible Accessories

Product codes

For even more technical details please see product operating manual.

Key Technologies

Smart Active Monitoring (SAM™) and GLM™ calibration technology

Active Crossovers

Directivity Control Waveguide (DCW™) Technology

Intelligent Signal Sensing (ISS™) Technology

Iso-Pod™ Stand

Minimum Diffraction Enclosure (MDE™) Technology

Optimised Amplifiers

Protection Circuitry

Reflex Port Design

Versatile Mountings

Networked Smart Active Monitor (SAM™) Systems feature automatic calibration to the environment.

Now, more than ever, audio productions are engineered in tighter, more confined working environments. This increases acoustic problems and lowers the reliability of monitoring. At the same time, an audio engineer's need to trust a reliable and precise monitoring system that reproduces sound neutrally and without distortion has not changed.

Built upon the solid electro-acoustic foundations of our 1200, 8000 and 7000 Series products, Genelec SAM Systems are today’s most advanced and flexible monitoring solutions. They are an indispensable tool for audio professionals, as they automatically adapt to the acoustic environment and correct for level, delay and room anomalies. SAM Systems are controlled using Genelec's proprietary Loudspeaker Manager (GLM™) network and software, enabling you to build a highly flexible and reliable monitoring system.

GLM is a highly intuitive and powerful monitor control networking system that manages connectivity to all SAM studio monitors and subwoofers on the network. GLM software features adjustment of level, distance delay and flexible room response compensation equalisation with our state-of-the-art, highly robust AutoCal™ 2 algorithm automated calibration system. All parameters and settings are stored in system setup files or saved in each individual monitor or subwoofer, if the GLM network needs to be disconnected.

Also, all acoustical features of SAM Systems can be optimised and tailored for different working styles or client demands. Additionally, even if the monitors or the production projects move between rooms, you can expect SAM technology to provide the highest consistency in monitoring, providing neutral soundstage imaging with low distortion – in each environment.

Genelec SAM Systems offer a comprehensive, solution-oriented, intelligently networked product range supporting analogue and digital signals in virtually any working environment.

Active crossover operating at low signal levels.

Audio electronic crossovers allow the audio signal to be split into separate frequency bands that are separately routed to individual power amplifiers, which are then connected to specific transducers optimised for a particular frequency band.

Active crossovers come in both digital and analogue varieties. Genelec digital active crossovers include additional signal processing, such as driver protection, delay, and equalisation.

Genelec analogue active crossover filters contain electronic components that are operated at low signal levels suitable for power amplifier inputs. This is in contrast to passive crossovers that operate at the high signal levels of the power amplifier's outputs, having to handle high currents and, in some cases, high voltages.

In a typical two-way system the active crossover needs two power amplifiers — one for the woofer and one for the tweeter.

The active crossover design offers multiple benefits:

- The frequency response becomes independent of any dynamic changes in the driver's electrical characteristics or the drive level.

- There is increased flexibility and precision for adjusting and fine-tuning each output frequency response for the specific drivers used.

- Each driver has its own signal processing and power amplifier. This isolates each driver from the drive signals handled by the other drivers, reducing inter-modulation distortion and overdriving problems.

- The ability to compensate for sensitivity variations between drivers.

- The possibility to compensate for frequency and phase response anomalies associated with a driver’s characteristics within the intended pass-band.

- The flat frequency response of a high-quality active loudspeaker is a result of the combined effect of the crossover filter response, power amplifier responses and driver responses in a loudspeaker enclosure.

Using the active approach enables frequency response adjustments and optimisation of the full loudspeaker system, placed in various room environments, without expensive external equalisers. The end result is a simpler, more reliable, efficient, consistent and precise active loudspeaker system.

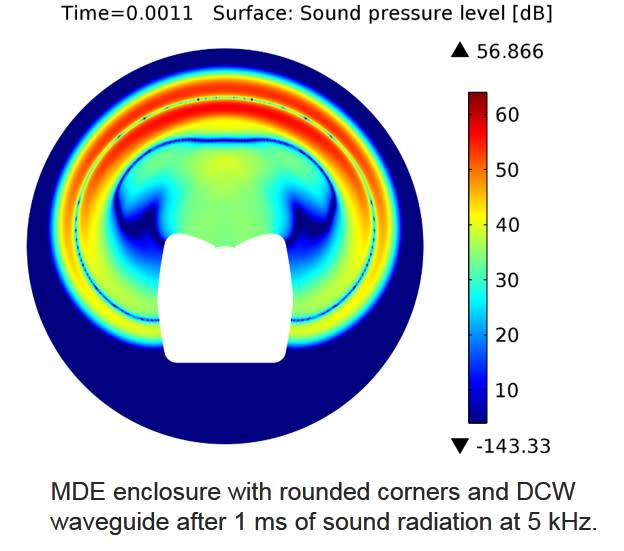

Directivity Control Waveguide (DCW™) for flat on and off-axis response.

A revolutionary approach was taken by Genelec in 1983 with the development of its Directivity Control Waveguide (DCW™). We have developed and refined this technology over more than 30 years to greatly improve the performance of direct radiating multi-way monitors.

The DCW technology shapes the emitted wavefront in a controlled way, allowing predictable tailoring of the directivity (dispersion) pattern. To make the directivity uniform and smooth, the goal is to limit the radiation angle so that the stray radiation is reduced. It results in excellent flatness of the overall frequency response as well as uniform power response. This minimises early reflections and provides a wide and controlled listening area achieving accurate sound reproduction on and off-axis.

Minimised early reflections and controlled, constant directivity have another important advantage: the frequency balance of the room reverberation field is essentially the same as the direct field from the monitors. As a consequence, the monitoring system's performance is less dependent on room acoustic characteristics.

Sound image width and depth, critical components in any listening environment, are important not only for on-axis listening, but also off-axis. This accommodates not only the engineer doing their job, but also others in the listening field, as is so often the case in large control rooms.

DCW™ Technology key benefits:

- Flat on and off-axis response for wider usable listening area.

- Increased direct-to-reflected sound ratio for reduced control room coloration.

- Improved stereo and sound stage imaging.

- Increased drive unit sensitivity up to 6 dB.

- Increased system maximum sound pressure level capacity.

- Decreased drive unit distortion.

- Reduced cabinet edge diffraction.

- Reduced complete system distortion.

Intelligent Signal Sensing (ISS™) for power consumption reduction in stand-by mode.

Introduced early 2013, Genelec’s Intelligent Signal-Sensing technology has been developed to meet with both European Union ErP Directives and Genelec's own ambitious sustainability standards.

The Intelligent Signal Sensing, ISS™ circuitry tracks the signal input of the loudspeaker and detects if it is in use. If the ISS circuit does not find any audio on the input for a period of time, it sets the loudspeaker to a low-power sleep state and the loudspeaker will consume less than 0.5 watts. When an input signal is detected, the loudspeaker immediately turns itself on.

Additionally an ‘ISS Disable’ switch is located on each product’s back plate next to the other room response controls. First, when the mains power switch of the loudspeaker is set to 'ON', the ISS™ auto-start function (low-power sleep state on/off) of the loudspeaker is active.

If this function is not desired, the ISS™ function can be disabled by setting the 'ISS Disable' switch on the back panel to 'ON' position. In this mode, the monitor is only powered on and off using the mains power switch.

Note that the mains power switch will always turn the monitor off completely.

Vibration decoupling Iso-Pod™ stand improves sound image definition.

Although it is advisable to use sturdy and stable floor stands together with free-standing loudspeakers, a very common solution is to place loudspeakers directly on a table or on a console meter bridge.

This causes several detrimental side effects. Aiming of the loudspeaker axis towards the listener is rarely implemented, also, unwanted mechanical vibration do propagate from the loudspeaker to the mounting surface, and first order reflection on the work surface causes comb filtering and hence ripples in the frequency response.

To solve these very common problems Genelec developed an efficient and very practical solution. We designed a loudspeaker stand called Iso-Pod™ - Isolation Positioner/Decoupler that is attached to the aluminium enclosure. It has four shallow feet and it is made from special lossy rubber-like material. It is firmly attached to the enclosure so that it can be slid along the curved bottom or side surface to allow for a ±15° tilt of the loudspeaker.

The loudspeakers’ acoustical axis can then be pointed precisely towards the listener by adjusting the enclosure’s inclination with the Iso-Pod. The vibration isolation and damping properties reduce midrange coloration caused by unwanted vibration transmitted to supporting surfaces.

This innovative solution is an integral part of Genelec loudspeaker design and provides clear benefits in usability and sound quality.

Minimum Diffraction Enclosure (MDE™) for uncoloured sound reproduction.

A common problem with standard free-standing loudspeakers is that the front baffle discontinuities cause diffractions and the loudspeaker sharp corners act as secondary sources through reflections.

In order to improve the flatness of the frequency response and the power response of free standing loudspeaker systems, Genelec have designed a highly innovative enclosure optimized to match the properties of the monitor drivers, featuring rounded edges, and gently curved front and sides. In addition to achieving an unsurpassed flatness of the frequency response, the enclosure having minimum diffractions yields superb sound stage imaging qualities.

To achieve such a smooth and elegantly curved cabinet surface and to reduce the outer dimensions of the enclosure, maximising at the same time the internal volume for improved low frequency efficiency, we designed a cabinet made off die-cast aluminium. Aluminium is lightweight, stiff and very easy to damp to yield a “dead” structure. The cabinet walls can be made fairly thin, providing at the same time good EMC shielding and excellent heat sink for the power amplifiers. Die-casting is made in two parts, front and rear, and they are easy to separate for potential servicing needs.

The DCW waveguide has been integrated in the MDE aluminium enclosure to provide improved control of the loudspeaker’s directivity. Basically, the low frequency limit for constant directivity is determined by the size of the waveguide, so the larger the surface the better the control. With a very controlled off-axis radiation, the listening window becomes consistent, which is of utmost importance with multi-channel audio monitoring. Controlled directivity also reduces possible first order reflections on surfaces near the loudspeaker, helping to provide consistent audio reproduction in different acoustical environments. In fact, the entire front baffle is gently curved and the acoustically transparent grilles are part of the outer cabinet aesthetics, blending perfectly with the various other curved surfaces.

Each transducer is driven by its own optimised amplifier.

Audio electronic crossovers allow to split the audio signal into separate frequency bands that can be separately routed to individual power amplifiers, which are then connected to specific transducers optimised for a particular frequency band.

In a typical 2-way loudspeaker system, the active crossover needs two power amplifiers — one for the woofer and one for the tweeter. The power amplifiers are connected directly to the drivers of an active loudspeaker, resulting in the power amplifier’s load becoming much simpler and well known. Each driver-specific power amplifier has only a limited frequency range to amplify (the power amplifier is placed after the active crossover) and this adds to the ease of design.

The active design principle offers multiple benefits:

- The power amplifiers are directly connected to the speaker drivers, maximising the control exerted by the power amplifier’s damping on the driver’s voice coil, reducing the consequences of dynamic changes in the driver electrical characteristics. This may improve the transient response of the system.

- There is a reduction in the power amplifier output requirement. With no energy lost in the passive crossover filter components, the amplifier power output requirements are reduced considerably (by up to 1/2 in some cases) without any reduction in the acoustic power output of the loudspeaker system. This can reduce costs and increase audio quality and system reliability.

- No loss between amplifier and driver units results in maximum acoustic efficiency.

- Active technology can achieve superior sound output vs. size vs. low frequency cut-off performance.

- All loudspeakers are delivered as a factory aligned system (amplifiers, crossover electronics and enclosure-driver systems).

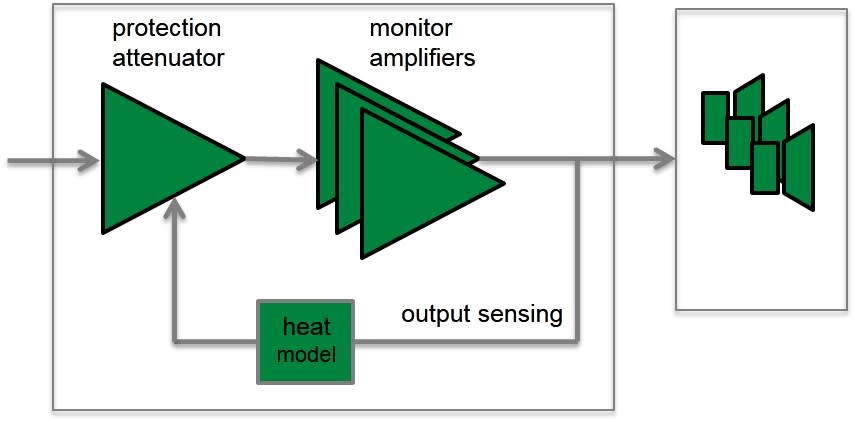

Sophisticated drive unit protection circuitry for safe operation.

When working in critical audio production environments it is essential that monitoring systems remain reliable and functional at all times. One of the main reasons behind Genelec’s excellent success in broadcasting environments is the reliability of our products and a key element behind the reliability is the internal protection circuitry found in all products since 1978.

The protection circuitry prevents driver failures by detecting signal levels, and in case of sudden peaks or constantly too high levels, taking the signal level down automatically. Of course this feature does not affect the sound quality in any way when working within the specifications of the loudspeaker, but only prevents inadequate input signals from breaking the loudspeaker.

Protection circuitry features and benefits:

- Reduces the output level when required, (e.g. when driver voice coil temperature reaches the safe limit), which highly improves system reliability.

- Appropriate protection circuitry design in every loudspeaker and subwoofer enables the maximisation of system output sound level.

Advanced reflex port design for extended low frequency response.

Genelec’s choice for vented, or reflex, enclosures dates back to the S30 model, the first Genelec product from 1978. Port performance has been improved and refined over the years with the aim to increase the woofer’s low frequency extension and sound pressure level capability to provide outstanding bass articulation and definition.

Both driver and vent contribute to the total radiation of a reflex enclosure. Most radiation comes from the driver, but at the vent-enclosure resonant frequency the driver displacement amplitude is small and most of the radiation comes out of the vent.

To minimise the air speed in the tube, the cross sectional area of the vent should be large. This in turn means that the vent tube has to be long which presents quite a design challenge.

The long, curved tube maximises airflow so deep bass can be reproduced without compression. The reflex tube terminates with a wide flare located on the rear of the enclosure, minimising port noises and providing excellent bass articulation.

The curvature of the tube has also been carefully designed to minimise any audible noise, compression or distortion. The inner end of the tube has proper resistive termination to minimise once again audible chuffing noise and air turbulence.

Proper reflex port design allows also to significantly reduce the woofer’s displacement, improving the linear low frequency output capacity.

Versatile mounting options for all installation needs.

In addition to perfect acoustical design and advanced tailoring options to optimize the loudspeaker’s behaviour to the room environment, Genelec loudspeakers offer a variety of mounting options for easy installation in different applications.

Our wide range of accessories and fixed mounting points on the back of our aluminium enclosure products offer solutions to all common installation situations. M6 support points have been integrated in the die-cast enclosure for wall and ceiling mounts.

Some models also feature a 3/8” thread at the bottom of the enclosure to fit a robust microphone stand. Other larger and heavier models feature M10 fixing points. Special floor stand plates have been designed in order to fit the Iso-Pod stand that is part of our product design.

With these features our loudspeakers have found their way to a variety of applications beyond the professional audio and studio world, for example in commercial and AV installation projects as well as in home environments all around the world.

References

Genelec | Exploring gamified immersive sound art with acclaimed Composer Juan Carlos Vasquez

Using GLM | Walkthrough

Using GLM | The foundations

Using GLM | Controlling GLM with MIDI

Using GLM | GRADE Room Acoustic Report

Using GLM | Calibration Group IDs

Using GLM | Accounts and product registration

Using GLM | The technical details

"The latest monitors in Genelec’s 8 series come in new APM packs, with room analysis and correction tools. We put them to the test."

-Bob Thomas, the author of the review article

{"fi-FI":"Sound on Sound Magazine's review of 8320 and 8330 studio monitors. The review was published in May 2015, and it is written by Bob Thomas.","ru-RU":"Sound on Sound Magazine's review of 8320 and 8330 studio monitors. The review was published in May 2015, and it is written by Bob Thomas.","de-DE":"Sound on Sound Magazine's review of 8320 and 8330 studio monitors. The review was published in May 2015, and it is written by Bob Thomas.","en-US":"Sound on Sound Magazine's review of 8320 and 8330 studio monitors. The review was published in May 2015, and it is written by Bob Thomas.","sv-SE":"Sound on Sound Magazine's review of 8320 and 8330 studio monitors. The review was published in May 2015, and it is written by Bob Thomas.","es-ES":"Sound on Sound Magazine's review of 8320 and 8330 studio monitors. The review was published in May 2015, and it is written by Bob Thomas."}

Documentation

Documents

Operating Manual 8320A Brochure 8320A SAM™ Series Full Line Catalogue In-Room Product Performance Immersive Solutions Brochure Operating Manual 8320 & 8330 - Chinese Version Genelec Home Studio Audio Monitoring Guide (2023) Genelec Home Studio Audio Monitoring Guide (German version)Downloads

Line Drawings (PDF) 8320A Line Drawings (DWG) 8320A 8320A - Simulation File (EASE3) 8320A - Simulation File (EASE4) 8320A - Simulation File (CLF)FAQ

There are several improvements in the new 83xx products. The capability to adapt to the room acoustics has been improved greatly, and, for example, 8320 and 8330 products provide four to five times higher number of tools for room response compensation compared to the 82xx products. The delay alignment capability has been expanded from about 80 ms to about 200 ms in 83xx. 83xx have been time-equalized internally to have a constant input-to-output delay above 400 Hz. 83xx products can level align by 60 dB.

All 83xx and 73xx products support distributed bass management, enabling the audio signal to be passed unmodified from the source and through the subwoofer into the monitors. 73xx subwoofers support a multichannel analogue audio signal and stereo AES/EBU digital audio signal.

"The latest monitors in Genelec’s 8 series come in new APM packs, with room analysis and correction tools. We put them to the test."

-Bob Thomas, the author of the review article

Sound on Sound Magazine's review of 8320 and 8330 studio monitors. The review was published in May 2015, and it is written by Bob Thomas.

hello

Got Questions?

Search our support portal for articles on frequently asked questions:

You can also submit an enquiry to our customer support team here.