High headroom three-way with unbelievable imaging. The 8341A is the point source monitor with the perfect blend of size and performance.

8341A

SAM™ Studio Monitor

Smart Active Monitoring (SAM™) and GLM™ calibration technology

Minimum Diffraction Coaxial (MDC™) Driver Technology

SPL

110 dB

Frequency Response

38 Hz - 37 kHz (-6 dB)

Dimensions

H 370 x W 237 x D 243 mm, with Iso-Pod™ (view in inches)

Work faster, for longer

For applications calling for extraordinary imaging, extended frequency response, short to medium listening distance or long, fatigue-free working hours, The Ones are in an elite league of their own. They promote faster and more consistent decision making, and they also extend listening time, because unnatural imaging - a main contributor to listener fatigue - is minimised.

Mixes that translate

As bigger brother to the super-compact 8331A, the 8341A offers increased LF extension and a higher SPL capability, so is ideally suited to slightly longer listening distances. In conjunction with our GLM calibration software, the 8341A will also compensate for detrimental room acoustics and distance delay, regardless of whether you work in mono, stereo or immersive formats. So now you can deliver mixes that translate beautifully - every time.

8341A

Awards

Genelec's The Ones monitors were awarded a "Producto del Año 2017" award by Hispasonic.

Genelec SAM™ Coaxial Studio Monitors 8331, 8341 and 8351, also known as "The Ones", were awarded with the MusicTech Gear of the Year 2017 award in "Product of the Year" -category.

Genelec's The Ones monitor series was awarded a Super AV Award 2017 in the category of Outstanding Overall Performance.

Genelec SAM™ Coaxial Studio Monitors 8331, 8341 and 8351, also known as "The Ones", were awarded with the MusicTech Gear of the Year 2017 award in "The Best Monitors" -category.

Genelec's The Ones monitors were awarded a IFTT C&C Award 2017 (International Film and Television Technology Creative & Craft Award).

Genelecs The Ones monitors were awardede a Beijing International Music & Hi-Fi Show award 2017 in the category of "Most Influential Product".

Genelec SAM™ Coaxial Studio Monitors 8331, 8341 and 8351, also known as "The Ones", were awarded a SOS Global Readers Award 2018 in "Highly Commended" -category.

Genelec 8331 and 8341 Compact Coaxial Monitors were awarded a TEC (Technical Excellence and Creativity) Award 2018 in the category of Studio Monitor Technology.

Genelec's The Ones series monitors were awarded a Resolution Award 2018 in the "Monitoring" category.

Technical Specifications

SPL

110 dB

Amplifier Power

250 W Bass (Class D) + 150 W Midrange (Class D) + 150 W Treble (Class D)

Frequency Response

38 Hz - 37 kHz ("-6 dB")

Accuracy of Frequency Response

± 1.5 dB (45 Hz - 20 kHz)

Driver Dimensions

2 x H 90 x W 170 mm Bass + ⌀ 90 mm Midrange + ⌀ 19 mm Treble (view in inches)

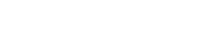

Dimensions

H 370 x W 237 x D 243 mm, with Iso-Pod™ (view in inches)

Weight

9.8 kg / 21.6 lb

Connections

1 x XLR Analog Input

1 x XLR AES/EBU Input

1 x XLR AES/EBU Output

2 x RJ45 Control

8341A SAM™ Studio Monitor

SAM™ Studio Monitor

Technical Specifications

High headroom three-way with unbelievable imaging. The 8341A is the point source monitor with the perfect blend of size and performance.

System Specifications

Frequency Response

45 Hz - 20 kHz (± 1.5 dB)

Low cutoff -6dB

38 Hz

High cutoff -6dB

37 kHz

SPL

Peak SPL Maximum peak acoustic output per pair in a listening room with music material at 1 m.

≥118 dB

Short term max SPL Maximum short term sine wave acoustic output on axis in half space, averaged from 100 Hz to 3 kHz at 1 m.

≥110 dB

Long term max SPL Maximum long term RMS acoustic output in the same conditions with IEC weighted noise (limited by driver protection circuit) at 1 m.

≥101 dB

Self-generated noise

Self-generated noise Self generated noise level in free space at 1 m on axis (A-weighted).

≤3 dB SPL

Weight

Weight9.8 kg (21.6 lb)

Dimensions

Height

351 mm

Height with Iso-Pod

370 mm

Width

237 mm

Depth

243 mm

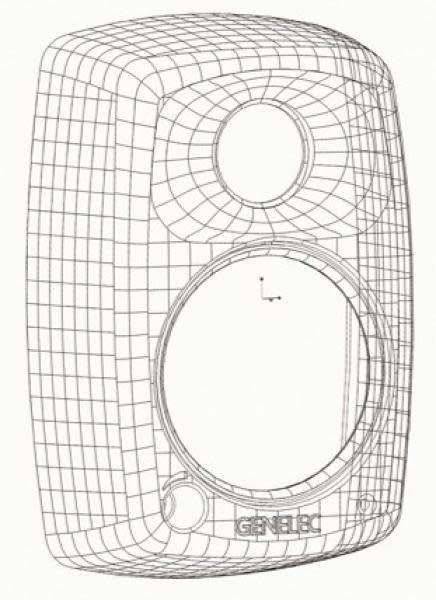

Enclosure

Enclosure material

Die cast aluminium

Enclosure type

Reflex port

Drivers

Driver type

Racetrack

8341A bass driver

Count

2

Width

170 mm

Height

90 mm

Driver type

Coaxial

8341A midrange driver cone (coaxial)

Diameter

90 mm

Driver type

Coaxial

8341A treble driver metal dome (coaxial)

Diameter

19 mm

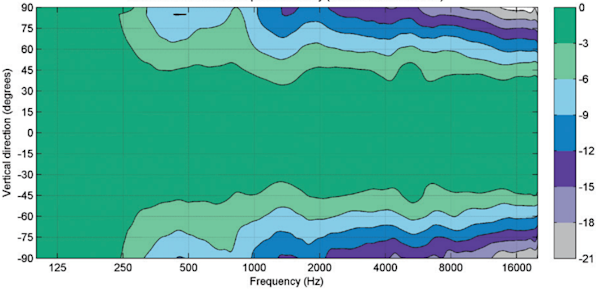

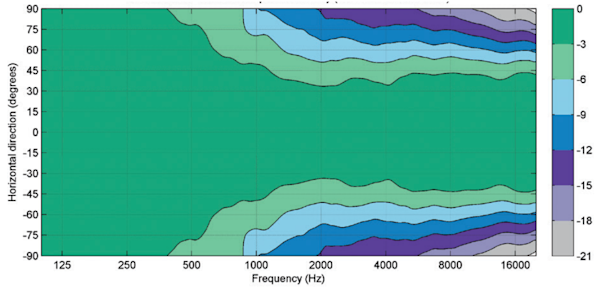

Directivity

Harmonic distortion

> 100 Hz ≤0.5 %

Group delay

The latency at high frequencies from the input to the acoustic output, measured in the analog input:

Extended Phase Linearity in GLM set to OFF (top graph)

3.3 ms

Extended Phase Linearity in GLM set to ON (bottom graph)

7.0 ms

In Genelec performance graphics, the time of converting the from an electronic input signal to the acoustic output in a Genelec monitor is described by two factors – latency and group delay. The group delay factor can be read in the graphics for a specific frequency. The total frequency-specific input-to-output delay is a sum of the latency and group delay factors. To understand the significance of this total delay, consider that moving a loudspeaker away by 1 meter creates an additional delay of about 3 ms.

Amplifier Section

Amplifiers

250 W Class D

150 W Class D

150 W Class D

Mains voltage

100-240 VAC 50/60Hz

Power consumption

ISS Active

≤0.5 W

Idle

≤16 W

Full output

250 W

Signal processing section

Connectors

Input Analog signal input connector XLR female, balanced 10 kOhm.

Input Digital signal input connector XLR female 110 Ohm.

Output Digital signal output / Thru connector XLR male 110 Ohm.

2 x Control Two CAT5 (RJ45) GLM Network connectors for computer control using the Genelec Loudspeaker Manager (GLM) software.

Crossover

Bass/Mid

500 Hz

Mid/Treble

3000 Hz

Product Variants

Product codes

Compatible Accessories

Product codes

For even more technical details please see product operating manual.

Key Technologies

Smart Active Monitoring (SAM™) and GLM™ calibration technology

Minimum Diffraction Coaxial (MDC™) Driver Technology

Acoustically Concealed Woofers (ACW™) Technology

Active Crossovers

Directivity Control Waveguide (DCW™) Technology

Intelligent Signal Sensing (ISS™) Technology

Iso-Pod™ Stand

Minimum Diffraction Enclosure (MDE™) Technology

Optimised Amplifiers

Protection Circuitry

Reflex Port Design

Versatile Mountings

Networked Smart Active Monitor (SAM™) Systems feature automatic calibration to the environment.

Now, more than ever, audio productions are engineered in tighter, more confined working environments. This increases acoustic problems and lowers the reliability of monitoring. At the same time, an audio engineer's need to trust a reliable and precise monitoring system that reproduces sound neutrally and without distortion has not changed.

Built upon the solid electro-acoustic foundations of our 1200, 8000 and 7000 Series products, Genelec SAM Systems are today’s most advanced and flexible monitoring solutions. They are an indispensable tool for audio professionals, as they automatically adapt to the acoustic environment and correct for level, delay and room anomalies. SAM Systems are controlled using Genelec's proprietary Loudspeaker Manager (GLM™) network and software, enabling you to build a highly flexible and reliable monitoring system.

GLM is a highly intuitive and powerful monitor control networking system that manages connectivity to all SAM studio monitors and subwoofers on the network. GLM software features adjustment of level, distance delay and flexible room response compensation equalisation with our state-of-the-art, highly robust AutoCal™ 2 algorithm automated calibration system. All parameters and settings are stored in system setup files or saved in each individual monitor or subwoofer, if the GLM network needs to be disconnected.

Also, all acoustical features of SAM Systems can be optimised and tailored for different working styles or client demands. Additionally, even if the monitors or the production projects move between rooms, you can expect SAM technology to provide the highest consistency in monitoring, providing neutral soundstage imaging with low distortion – in each environment.

Genelec SAM Systems offer a comprehensive, solution-oriented, intelligently networked product range supporting analogue and digital signals in virtually any working environment.

Minimum Diffraction Coaxial (MDC™) Driver Technology reproduces outstanding sound image.

Typical coaxial designs suffer from a somewhat ragged frequency response due to diffraction problems inherent in their unrefined design. However, crossover issues due to the non-coincident location of sources are solved with a coaxial configuration, so a coaxial solution without diffraction problems is the ideal. Genelec’s Minimum Diffraction Coaxial (MDC™) Driver Technology provides all the benefits of coaxial design while overcoming the typical shortages – solving the diffraction problem.

The first step is to minimise the cone displacement, in other words to limit the low frequency bandwidth of the driver. Next, is to avoid all sources of diffractions. The main structure of the MDC design consists of an integrated MF diaphragm-suspension tweeter construction. The visible part of the coaxial driver is formed by the curved flexible skin with the dome tweeter assembly in its centre. The inner section joins the cone to the tweeter without any acoustical discontinuity, and the outer one does the same between the cone and the driver chassis.

As there are no acoustically observable discontinuities between the tweeter and the cone, just a smooth surface, there is no diffraction either. The cone profile is very carefully optimised to form an integrated directivity control waveguide for the tweeter radiation. The driver outer edge is terminated to a normal Genelec DCW in order to control the dispersion of midrange radiation as well. The response is very smooth both on and off-axis and free from any anomalies – and directivity is well controlled.

This breakthrough in coaxial design provides improved imaging and overall sound quality on and off-axis, extremely smooth frequency response leading to outstanding clarity and definition of the inner details of the music.

The main novelties of Genelec combined DCW™ and MDC™ designs:

- Diffraction-free joint between tweeter and midrange diaphragm.

- Diffraction-free joint between midrange diaphragm and DCW™ waveguide.

- A proprietary midrange diaphragm technology – laminate structure combining a rigid cone and elastic, lossy materials including the suspension itself.

- A midrange diaphragm-suspension pair which cancels all possible non-linearity.

Advantages:

- Smoother frequency response.

- Ensures the drivers couple coherently over their full operating bandwidth.

- Significantly improves the directivity control in the critical frequency range.

- Provides balanced suspension dynamics to minimise acoustic distortion.

- Optimises the use of the front baffle area while maintaining the 8000 Series appearance and benefits.

Acoustically Concealed Woofers (ACW™) for controlled directivity down to low frequencies.

The 8351 Acoustically Coaxial Three-way system features our novel Acoustically Concealed Woofer (ACW™) technology. The Acoustically Concealed Woofers radiate through slots located on both ends of the enclosure.

The 8351 features two woofers and the positions of the two woofers have been chosen to extend the coaxial acoustical radiation concept towards low frequencies. In terms of low frequency directivity, when two woofers are used, separated by a distance, the system of two woofers behaves acoustically like one giant woofer spanning the distance between the two woofers. Also, such a dual woofer design extends the control of the directivity to low frequencies along the largest front baffle dimension.

The ACW technology makes the woofer openings and the woofer drivers acoustically invisible to the acoustical radiation from the minimum diffraction coaxial (MDC™) driver responsible for the midrange and tweeter frequencies. The radiation openings are optimized for size and curvature to minimize any acoustic diffractions.

The ACW solution also allows us to use the whole front baffle surface of the 8351 as one giant Directivity Control Waveguide (DCW™) that is part and built into a Minimum Diffraction Enclosure (MDE™).

The 8351 ACW arrangement creates a monitor that has a physically compact size yet behaves like a much larger system in terms of low frequency directivity.

Such controlled low frequency directivity translates to improved quality of monitoring and smaller low frequencies interaction between the monitor and the room.

Active crossover operating at low signal levels.

Audio electronic crossovers allow the audio signal to be split into separate frequency bands that are separately routed to individual power amplifiers, which are then connected to specific transducers optimised for a particular frequency band.

Active crossovers come in both digital and analogue varieties. Genelec digital active crossovers include additional signal processing, such as driver protection, delay, and equalisation.

Genelec analogue active crossover filters contain electronic components that are operated at low signal levels suitable for power amplifier inputs. This is in contrast to passive crossovers that operate at the high signal levels of the power amplifier's outputs, having to handle high currents and, in some cases, high voltages.

In a typical two-way system the active crossover needs two power amplifiers — one for the woofer and one for the tweeter.

The active crossover design offers multiple benefits:

- The frequency response becomes independent of any dynamic changes in the driver's electrical characteristics or the drive level.

- There is increased flexibility and precision for adjusting and fine-tuning each output frequency response for the specific drivers used.

- Each driver has its own signal processing and power amplifier. This isolates each driver from the drive signals handled by the other drivers, reducing inter-modulation distortion and overdriving problems.

- The ability to compensate for sensitivity variations between drivers.

- The possibility to compensate for frequency and phase response anomalies associated with a driver’s characteristics within the intended pass-band.

- The flat frequency response of a high-quality active loudspeaker is a result of the combined effect of the crossover filter response, power amplifier responses and driver responses in a loudspeaker enclosure.

Using the active approach enables frequency response adjustments and optimisation of the full loudspeaker system, placed in various room environments, without expensive external equalisers. The end result is a simpler, more reliable, efficient, consistent and precise active loudspeaker system.

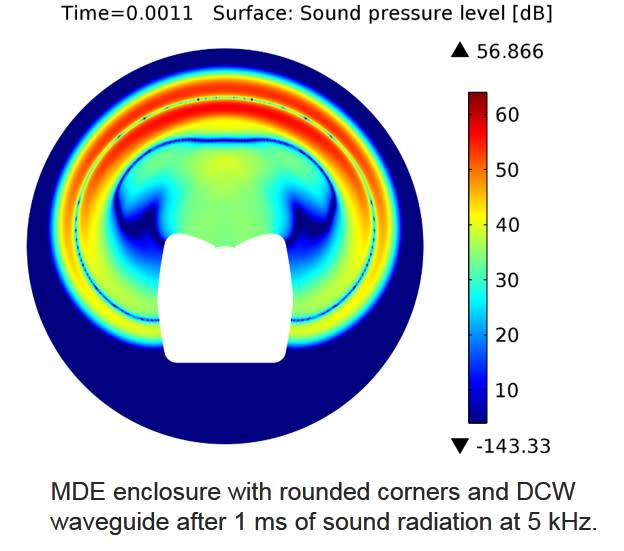

Directivity Control Waveguide (DCW™) for flat on and off-axis response.

A revolutionary approach was taken by Genelec in 1983 with the development of its Directivity Control Waveguide (DCW™). We have developed and refined this technology over more than 30 years to greatly improve the performance of direct radiating multi-way monitors.

The DCW technology shapes the emitted wavefront in a controlled way, allowing predictable tailoring of the directivity (dispersion) pattern. To make the directivity uniform and smooth, the goal is to limit the radiation angle so that the stray radiation is reduced. It results in excellent flatness of the overall frequency response as well as uniform power response. This minimises early reflections and provides a wide and controlled listening area achieving accurate sound reproduction on and off-axis.

Minimised early reflections and controlled, constant directivity have another important advantage: the frequency balance of the room reverberation field is essentially the same as the direct field from the monitors. As a consequence, the monitoring system's performance is less dependent on room acoustic characteristics.

Sound image width and depth, critical components in any listening environment, are important not only for on-axis listening, but also off-axis. This accommodates not only the engineer doing their job, but also others in the listening field, as is so often the case in large control rooms.

DCW™ Technology key benefits:

- Flat on and off-axis response for wider usable listening area.

- Increased direct-to-reflected sound ratio for reduced control room coloration.

- Improved stereo and sound stage imaging.

- Increased drive unit sensitivity up to 6 dB.

- Increased system maximum sound pressure level capacity.

- Decreased drive unit distortion.

- Reduced cabinet edge diffraction.

- Reduced complete system distortion.

Intelligent Signal Sensing (ISS™) for power consumption reduction in stand-by mode.

Introduced early 2013, Genelec’s Intelligent Signal-Sensing technology has been developed to meet with both European Union ErP Directives and Genelec's own ambitious sustainability standards.

The Intelligent Signal Sensing, ISS™ circuitry tracks the signal input of the loudspeaker and detects if it is in use. If the ISS circuit does not find any audio on the input for a period of time, it sets the loudspeaker to a low-power sleep state and the loudspeaker will consume less than 0.5 watts. When an input signal is detected, the loudspeaker immediately turns itself on.

Additionally an ‘ISS Disable’ switch is located on each product’s back plate next to the other room response controls. First, when the mains power switch of the loudspeaker is set to 'ON', the ISS™ auto-start function (low-power sleep state on/off) of the loudspeaker is active.

If this function is not desired, the ISS™ function can be disabled by setting the 'ISS Disable' switch on the back panel to 'ON' position. In this mode, the monitor is only powered on and off using the mains power switch.

Note that the mains power switch will always turn the monitor off completely.

Vibration decoupling Iso-Pod™ stand improves sound image definition.

Although it is advisable to use sturdy and stable floor stands together with free-standing loudspeakers, a very common solution is to place loudspeakers directly on a table or on a console meter bridge.

This causes several detrimental side effects. Aiming of the loudspeaker axis towards the listener is rarely implemented, also, unwanted mechanical vibration do propagate from the loudspeaker to the mounting surface, and first order reflection on the work surface causes comb filtering and hence ripples in the frequency response.

To solve these very common problems Genelec developed an efficient and very practical solution. We designed a loudspeaker stand called Iso-Pod™ - Isolation Positioner/Decoupler that is attached to the aluminium enclosure. It has four shallow feet and it is made from special lossy rubber-like material. It is firmly attached to the enclosure so that it can be slid along the curved bottom or side surface to allow for a ±15° tilt of the loudspeaker.

The loudspeakers’ acoustical axis can then be pointed precisely towards the listener by adjusting the enclosure’s inclination with the Iso-Pod. The vibration isolation and damping properties reduce midrange coloration caused by unwanted vibration transmitted to supporting surfaces.

This innovative solution is an integral part of Genelec loudspeaker design and provides clear benefits in usability and sound quality.

Minimum Diffraction Enclosure (MDE™) for uncoloured sound reproduction.

A common problem with standard free-standing loudspeakers is that the front baffle discontinuities cause diffractions and the loudspeaker sharp corners act as secondary sources through reflections.

In order to improve the flatness of the frequency response and the power response of free standing loudspeaker systems, Genelec have designed a highly innovative enclosure optimized to match the properties of the monitor drivers, featuring rounded edges, and gently curved front and sides. In addition to achieving an unsurpassed flatness of the frequency response, the enclosure having minimum diffractions yields superb sound stage imaging qualities.

To achieve such a smooth and elegantly curved cabinet surface and to reduce the outer dimensions of the enclosure, maximising at the same time the internal volume for improved low frequency efficiency, we designed a cabinet made off die-cast aluminium. Aluminium is lightweight, stiff and very easy to damp to yield a “dead” structure. The cabinet walls can be made fairly thin, providing at the same time good EMC shielding and excellent heat sink for the power amplifiers. Die-casting is made in two parts, front and rear, and they are easy to separate for potential servicing needs.

The DCW waveguide has been integrated in the MDE aluminium enclosure to provide improved control of the loudspeaker’s directivity. Basically, the low frequency limit for constant directivity is determined by the size of the waveguide, so the larger the surface the better the control. With a very controlled off-axis radiation, the listening window becomes consistent, which is of utmost importance with multi-channel audio monitoring. Controlled directivity also reduces possible first order reflections on surfaces near the loudspeaker, helping to provide consistent audio reproduction in different acoustical environments. In fact, the entire front baffle is gently curved and the acoustically transparent grilles are part of the outer cabinet aesthetics, blending perfectly with the various other curved surfaces.

Each transducer is driven by its own optimised amplifier.

Audio electronic crossovers allow to split the audio signal into separate frequency bands that can be separately routed to individual power amplifiers, which are then connected to specific transducers optimised for a particular frequency band.

In a typical 2-way loudspeaker system, the active crossover needs two power amplifiers — one for the woofer and one for the tweeter. The power amplifiers are connected directly to the drivers of an active loudspeaker, resulting in the power amplifier’s load becoming much simpler and well known. Each driver-specific power amplifier has only a limited frequency range to amplify (the power amplifier is placed after the active crossover) and this adds to the ease of design.

The active design principle offers multiple benefits:

- The power amplifiers are directly connected to the speaker drivers, maximising the control exerted by the power amplifier’s damping on the driver’s voice coil, reducing the consequences of dynamic changes in the driver electrical characteristics. This may improve the transient response of the system.

- There is a reduction in the power amplifier output requirement. With no energy lost in the passive crossover filter components, the amplifier power output requirements are reduced considerably (by up to 1/2 in some cases) without any reduction in the acoustic power output of the loudspeaker system. This can reduce costs and increase audio quality and system reliability.

- No loss between amplifier and driver units results in maximum acoustic efficiency.

- Active technology can achieve superior sound output vs. size vs. low frequency cut-off performance.

- All loudspeakers are delivered as a factory aligned system (amplifiers, crossover electronics and enclosure-driver systems).

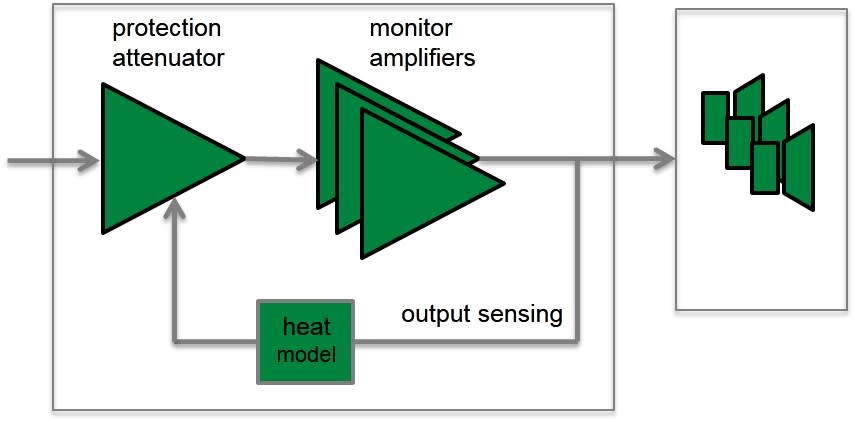

Sophisticated drive unit protection circuitry for safe operation.

When working in critical audio production environments it is essential that monitoring systems remain reliable and functional at all times. One of the main reasons behind Genelec’s excellent success in broadcasting environments is the reliability of our products and a key element behind the reliability is the internal protection circuitry found in all products since 1978.

The protection circuitry prevents driver failures by detecting signal levels, and in case of sudden peaks or constantly too high levels, taking the signal level down automatically. Of course this feature does not affect the sound quality in any way when working within the specifications of the loudspeaker, but only prevents inadequate input signals from breaking the loudspeaker.

Protection circuitry features and benefits:

- Reduces the output level when required, (e.g. when driver voice coil temperature reaches the safe limit), which highly improves system reliability.

- Appropriate protection circuitry design in every loudspeaker and subwoofer enables the maximisation of system output sound level.

Advanced reflex port design for extended low frequency response.

Genelec’s choice for vented, or reflex, enclosures dates back to the S30 model, the first Genelec product from 1978. Port performance has been improved and refined over the years with the aim to increase the woofer’s low frequency extension and sound pressure level capability to provide outstanding bass articulation and definition.

Both driver and vent contribute to the total radiation of a reflex enclosure. Most radiation comes from the driver, but at the vent-enclosure resonant frequency the driver displacement amplitude is small and most of the radiation comes out of the vent.

To minimise the air speed in the tube, the cross sectional area of the vent should be large. This in turn means that the vent tube has to be long which presents quite a design challenge.

The long, curved tube maximises airflow so deep bass can be reproduced without compression. The reflex tube terminates with a wide flare located on the rear of the enclosure, minimising port noises and providing excellent bass articulation.

The curvature of the tube has also been carefully designed to minimise any audible noise, compression or distortion. The inner end of the tube has proper resistive termination to minimise once again audible chuffing noise and air turbulence.

Proper reflex port design allows also to significantly reduce the woofer’s displacement, improving the linear low frequency output capacity.

Versatile mounting options for all installation needs.

In addition to perfect acoustical design and advanced tailoring options to optimize the loudspeaker’s behaviour to the room environment, Genelec loudspeakers offer a variety of mounting options for easy installation in different applications.

Our wide range of accessories and fixed mounting points on the back of our aluminium enclosure products offer solutions to all common installation situations. M6 support points have been integrated in the die-cast enclosure for wall and ceiling mounts.

Some models also feature a 3/8” thread at the bottom of the enclosure to fit a robust microphone stand. Other larger and heavier models feature M10 fixing points. Special floor stand plates have been designed in order to fit the Iso-Pod stand that is part of our product design.

With these features our loudspeakers have found their way to a variety of applications beyond the professional audio and studio world, for example in commercial and AV installation projects as well as in home environments all around the world.

References

Genelec | Nilento Studios goes immersive with ‘The Ones’ 7.1.4 Dolby Atmos system

Genelec Visits Morten Lindberg’s Stunning Immersive Audio Studio

One on One with Eicca Toppinen, Apocalyptica | Genelec 8341 | Interview

One on One Interview | Engineer Richard Chycki reflects on Genelec The Ones and GLM software

Review: Genelec The Ones

We are The Ones

Developing The Ones

Using GLM | Walkthrough

Using GLM | The foundations

Using GLM | Controlling GLM with MIDI

Using GLM | GRADE Room Acoustic Report

Using GLM | Calibration Group IDs

Using GLM | Accounts and product registration

Using GLM | The technical details

Genelec Visits Morten Lindberg’s Stunning Immersive Audio Studio

In the world of immersive music recording, no-one has done more than Grammy-winning sound engineer and music producer Morten Lindberg to set the gold standard for what can be achieved in this field.

We visited Morten at his incredible studio in Oslo, Norway to talk about his approach to immersive recording, and how his new 7.1.4 Genelec monitoring system has become an essential part of his workflow.

Welcome to a fascinating insight into the world of a true immersive audio pioneer.

One on One with Eicca Toppinen, Apocalyptica | Genelec 8341 | Interview

Eicca Toppinen, multi-instrumentalist, and co-founder of cello metal band Apocalyptica, says he doesn’t have a formula for writing music but is inspired by the sound of different instruments.

One on One Interview | Engineer Richard Chycki reflects on Genelec The Ones and GLM software

“I haven’t experienced this before, where I could take speakers to any studio and they always sound 100% consistent.”

We are The Ones

Iisalmi, Finland. 19th October 2012. Our journey begins with inspiration from our users around the world. That inspiration found its way to Ilpo Martikainen’s notebook, and now we’re finally here. We wanted The Ones to point the way to the future of audio monitoring.

Documentation

Documents

Operating Manual 8341A Brochure The Ones The Ones 产品手册 Immersive Solutions Brochure GENELEC真力-8341a-用户操作手册Downloads

8341A - Simulation File (CLF) Line Drawings (PDF) 8341A Line Drawings (DWG) 8341A The Acoustic Design of Minimum Diffraction Coaxial Loudspeakers with Integrated Waveguides 8341A - Simulation File (GLL)Reviews

Audio Media International: Genelec The Ones 8341A Headliner Magazine: Genelec 8341A Studio Monitor review Tape Op Review: 8341A SAM Monitors & GLM User Kit Production Expert: Genelec 8331 SAM & 8341 SAM "The Ones" Studio Monitors & GLM™ 3 - Do They Re-Write The Rule Book?, August 2018 (UK) Sound on Sound Magazine: Genelec The Ones by Hugh Robjohns, July 2017 (UK) MusicTech Magazine: Genelec The Ones SAM 8331 & 8341 Review – Raising The Bar, November 2017 (GB) Recording Magazine (PDF): Genelec 8341 and 8331 Studio Monitors and GLM 3 Software, March 2018 (US) Stereo Sound: 8331 & 8341 Review, November 2017 (Japan) Resolution Magazine/Monitoring Supplement: “Creating Ultimate Point Source”, May 2017 (GB)"These studio monitors pack a serious amount of technology into a very compact package. Can all this tech combat the issues associated with powerful rear ported designs and can the GLM™ 3 system cope with a truly dreadful set of listening circumstances?"

The Production Expert's comprehensive review "Genelec 8331 SAM & 8341 SAM "The Ones" Studio Monitors & GLM™ 3 - Do They Re-Write The Rule Book?" does not only list the pros and cons, but also describes the user experience of the products.

The review was published in August 2018.

"The culmination of years of R&D, these revolutionary new speakers offer performance way beyond what you’d expect from their size."

-Hugh Robjohns, the author of the review article

Sound on Sound Magazine's (UK) review of 8331, 8341 and 8351 SAM™ Studio Monitor. Written by Hugh Robjohns. Published July 2017.

Read the full review: Sound on Sound 8331, 8341 and 8351 Review

MusicTech Magazine's (GB) review of 8331 and 8341 SAM™ Studio Monitor. Published in November 2017.

MusicTech magazine's review of Genelec 8331 and 8341 studio monitors. The review is written by Andy Jones and it was published on MusicTech's website in November 2017.

"Two new 3-way coaxial monitors to fit any room—and software to ease the process."

Recording Magazine's (US) review of Genelec 8341 and 8331 studio monitors and GLM 3 software written by Paul Vnuk Jr. and Mike Metlay. The review was published in March 2018.

Read the full review: Recording Magazine 8331, 8341, and GLM 3™ Review

Stereo Sound Online Magazine's (JP) review of 8331 and 8341 SAM™ Studio Monitor. The review is written in Japanese and it was published in November 2017.

Stereo Sound Online Magazine's (JP) review of 8331 and 8341 SAM™ Studio Monitor. The review is written in Japanese and it was published in November 2017.

Read the full review: Stereo Sound 8331 & 8341 Review

"Collectively, the three monitors make up The Ones, a range combining the best of coaxial and point source to create what Genelec is calling Ultimate Point Source. Resolution speaks to Aki Mäkivirta to find out more."

Resolution Magazine Monitoring Supplement's (GB) review of The Ones. Published May 2017.

Read the full review: Resolution Magazine/Monitoring Supplement The Ones Review

hello

Got Questions?

Search our support portal for articles on frequently asked questions:

You can also submit an enquiry to our customer support team here.